CNC / Semiautomatic / Manual Butt Welding Machine ERBACH SM 630

Produced by ERBACH Kunststoff- und Schweißtechnik GmbH (Germany)

|

Technical specifications: Dimension range: 315-630 mm Detailed information about options can be found below |

|

ERBACH SM 630 Butt-Welding Machine consists of the following elements: basic frame, hydraulic station, heating mirror, planer, reduction inserts, support/case for planer and heating mirror, instruments and spare parts, transport box. |

||

|

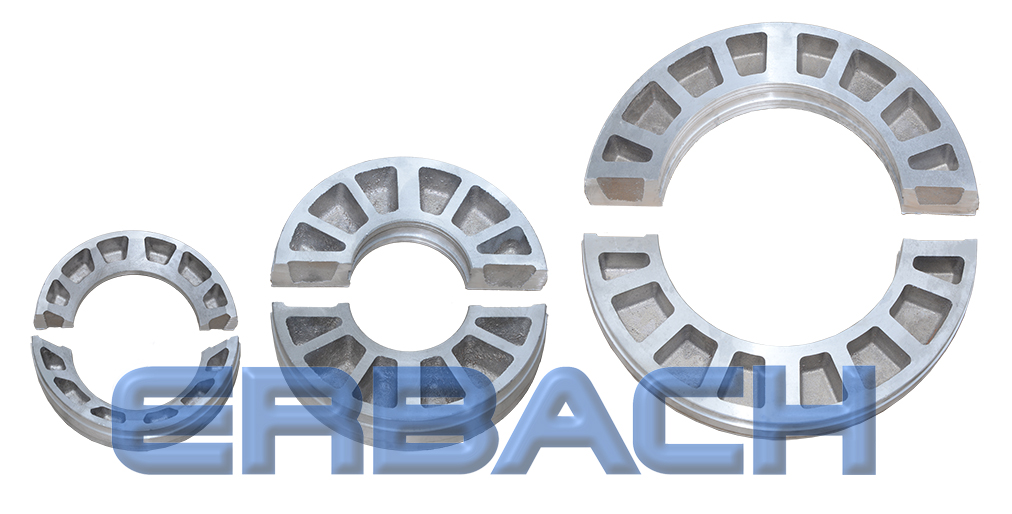

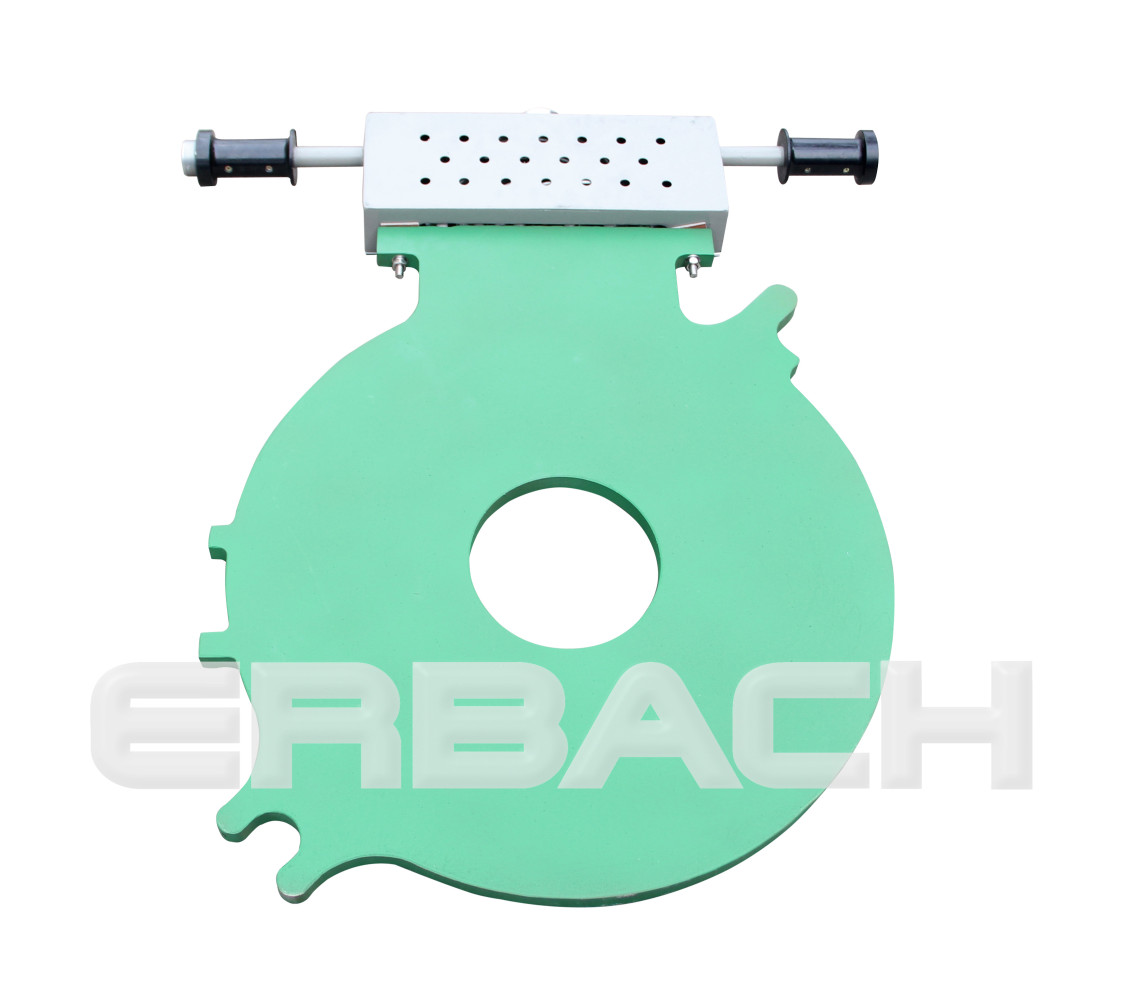

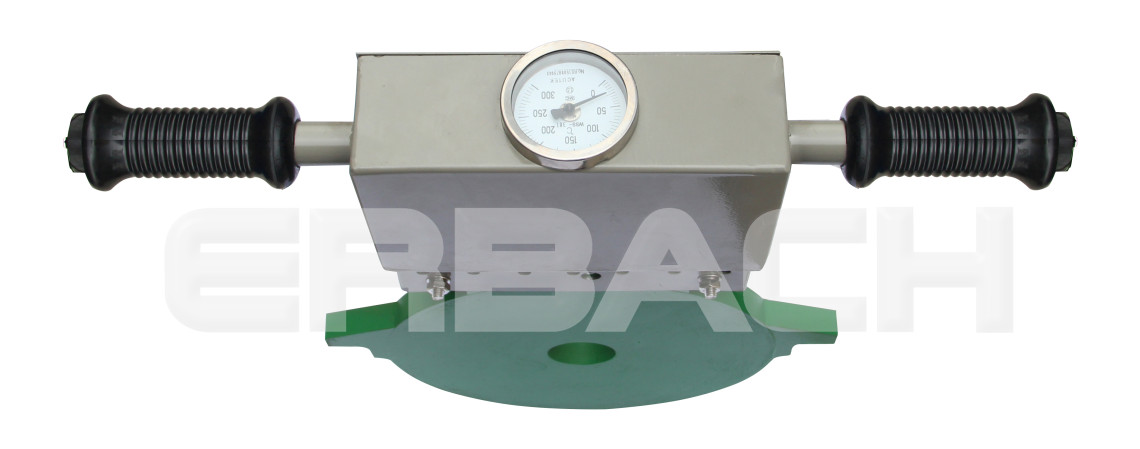

Basic Machine: Frame: Hydraulic drive, with two fixed and two movable clamping rings with an inner diameter of 630 mm. The position of the inner clamping ring is changable. With its large piston area, the machine has greater pressure reserves, resulting in high workpiece movement pressure, e.g. is important for longer pipelines or high pressure welding. Heating Mirror: Precise electronic thermostat maintains the set temperature with high accuracy. The three-layer Teflon coating is durable and has excellent non-stick properties. Additional control of the temperature of the heating mirror is made possible by an analogue thermometer, installed at the top of heating mirror handles area. This provides additional control of welding temperature. Regarding safety of personnel the measurement is always carried out even without electrical mains connection. There are higher number of reliable heaters inside the heating mirror, therefore the ERBACH® heating mirrors have a longer running time and a more uniform temperature distribution of the mirror surface. Hydraulic station: Excellent protection against dust and moisture, adapted for the climatic conditions in cold weather. The hydraulics contain hydraulic oil, type Schell Tellus (operating at -45 ° C ambient temperature). Over-voltage protection is installed, as well as a temperature controller, a pressure regulator, a bypass, a timer and a digital voltmeter. A USB port allows you to charge your phone or tablet. Quick-release couplings exclude oil spill and inadvertently incorrect connection. Planer: The planer of Erbach hydraulic butt-welding machines enabled with drive of large power reserves and high reliability. This is ensured by an optimally coordinated construction of the engine-gearbox block, which ensures high torque, more power and longer running time. Supporting case for the storage and transport of the planer and heating mirror Key for adjusting the clamp tightening screws; screwdriver, other instruments, set of spare parts Operating instructions, welding parameters charts Wooden transport box for transport and storage Set of reducing inserts |

|

|

|

|

||

| Reduction inserts (ISO) | Heating mirror with Teflon coating | Analog thermometer for additional control | Data logging device ERBACH R |

|

|

|

|

For detailed conditions of warranty and post-warranty service, please state the original date of purchase of the device. Warranty and after-warranty services are provided in an authorized-service center.